NOTE: WE DO NOT DO CUSTOM TOOLING FOR INDIVIDUAL MODELS! FULL CUSTOM TOOLED PROJECTS DESIGNED FROM THE TIRES UP BEGIN AT A MINIMUM OF 2,000 PIECES.

Producing a die-cast replica is an intricate process that involves design, tooling, casting, painting and assembly. The average truck can require upwards of 250 pieces to assemble! Here's a very simplified outline of how a replica is built...

STEP ONE: Beginning with a client's desire to have a replica produced, a project scope, budget and schedule are agreed upon. Once licensing is achieved from the OEM (original equipment manufacturer), we require CAD files from them in order to begin the process of designing the actual miniature.

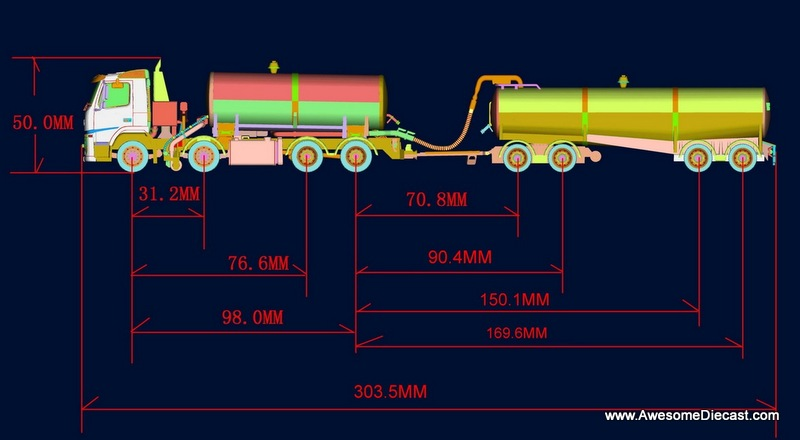

STEP TWO: 3-D CAD (computer aided-design) files are completed and approved by the client. Lengths are determined by the scale the client wants the replica built in.

STEP THREE: Preliminary tooling is created and hand samples are produced in Resin. These are sent to the client for approval, and then the actual process of casting the model from Zinc metal occurs. Once all the parts are cast, it's on to assembly, paint and quality control.

STEP FOUR: The result, a museum-quality replica of the real truck, just small enough to drive on a desk!

Contact us to see if we can deliver diecast vehicles for your brand!

Email | sales@AwesomeDiecast.com

Voice | North America: +1-866-277-4775 or International: +1-561-350-4045